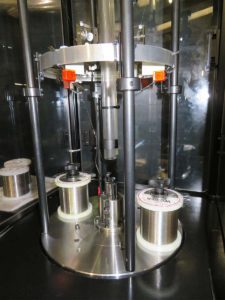

To support the growth in Kemtron’s core business we have developed a significant capital investment programme to improve and develop our plant and equipment. One of our newest installations is a pair of bespoke knitting machines.

We have spent time understanding the needs of this area and looking at the demand in the market to ensure we have reliable and consistent output across a variety of material and profiles. The new machines incorporate the latest safety critical features and provide easy maintenance and operation.

One of the major strengths of Kemtron is our technical and engineering background, this has enabled us to specify exactly what we require, design the equipment in-house and make most of the machine and components on site. As a result, we get machines that are tailored to our customers’ needs and specific to our industry. We have a dedicated well-resourced tool room and machining area that is able to make parts for our own use. This allows us to ensure a very level of high accuracy and gives us quick manufacturing times without the need to sub contract activities.

We are already seeing the benefit with reduced lead times, improved output and high quality product. ‘It is expected that our revenue in knitting could grow by up to 50% in the next six months and we have put ourselves in a great position to take advantage of the opportunity.’ said Victoria Tsoi, Managing Director.