Most electronic enclosures need some form of air ventilation to keep cool the electronics within. If this is a RFI/EMI shielded enclosure then the overall shielding effectiveness of the enclosure can be compromised.

For many commercial applications perforated sheet, metal or metallised plastic will suffice but for high performance requirements waveguides provide superior shielding over a wide frequency range. Waveguides can be circular, rectangular or honeycomb shaped. The principle is that of ‘Waveguide beyond cutoff’. The honeycomb vent is series of tubes that acts as a waveguide, guiding electromagnetic waves into or out of the enclosure, but as the tubes are long enough then it attenuates those waves. Typically, the tube should be at least 3 times as long as the diameter. Good practice is 4 times. Therefore a 3.18mm cell should be 12.7mm long.

The most cost effective is aluminium honeycomb because it offers high shielding performance, light weight and good airflow as it is 96% open area. A typical shielded enclosure will use 2 honeycomb ventilation panels one as the inlet and one for the exhaust.

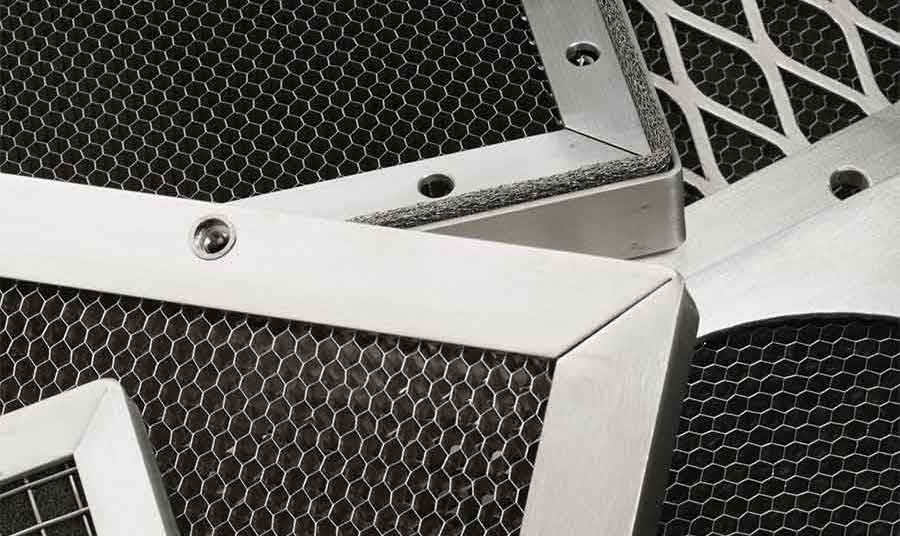

Aluminium honeycomb vents are supplied in an aluminium frame with an emi gasket to ensure a good electrically conductive bond with the enclosure. Many frame styles are available to suite different mounting methods.

Kemtron’s standard honeycomb vent uses 2 layers of 3.18mm cell X 6.4mm thick laid at 90°, this is known as cross cell. Cross cell honeycomb improves shielding performance by eliminating any polarizing effects.

Slant honeycomb 30°, 45° or 60° can also be supplied to stop any moisture running back down the honeycomb into the enclosure.

Typical shielding performance of a 12.7mm thick cross cell vent is:

- 200 KHz in H (magnetic field) – 71db

- 100 MHz in E (Electric field) – 105db

- 500 MHz in P (Plane wave) – 93db

- 2 GHz in P (plane wave) – 94db

- 10 GHz in P (Plane wave) – 90db

Kemtron’s standard finish (Kempass) for aluminium vent panels fully meets the RoHS directive and applies permanganate passivation which is a chromate free, inorganic and non toxic coating. The process produces a dense, uniform coating consisting of aluminium and reduced manganese oxides giving a light yellow colour to the surface. The surface finish is conductive with a low contact resistance. It also meets all requirements of MIL-C-5541E for corrosion and electrical conductivity. Surtec 650, tin or nickel plating finishes are also available. We are also able to offer a comprehensive range of painted finishes to match enclosure finishes or military colours.

To find out more information on our honeycomb vents, please click here.